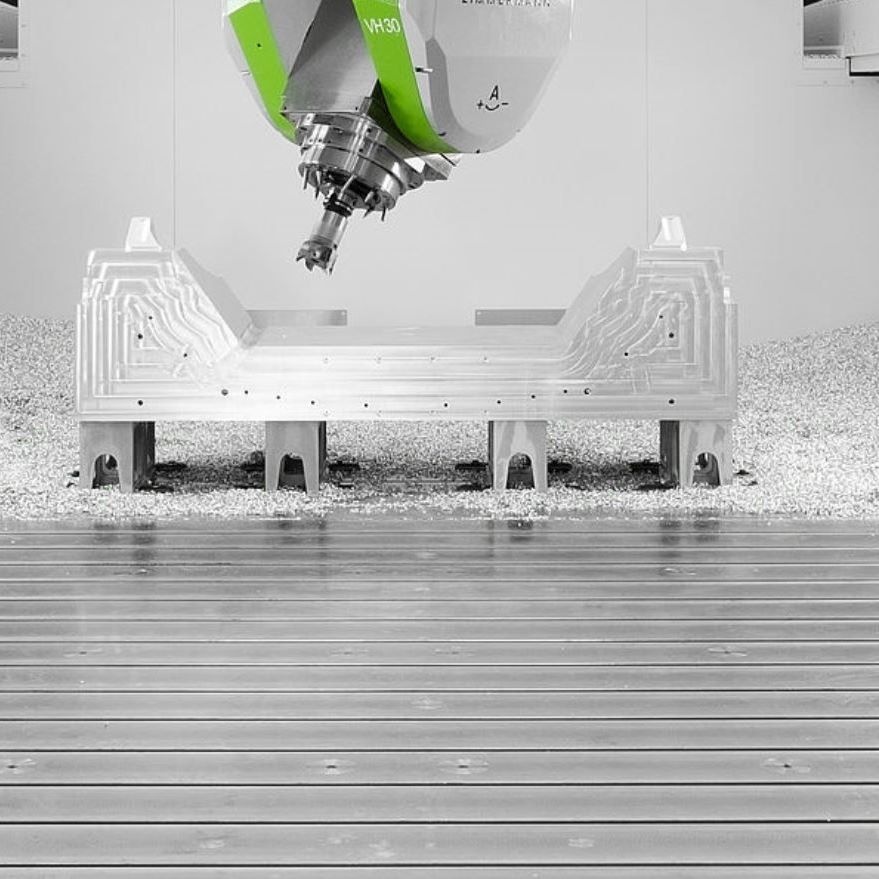

HIGH SPEED MACHINING CENTER

Wide range of 3-Axis, 5-Axis and even 6-Axis, High Speed Machining Center for wide range of application from Small Ultra Precision Molds to Large Size Automotive Molds, Aerospace Parts machining and Super FInishing Applications.

Coining Dies

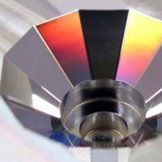

High Finish Moulds

Optical Moulds

Blisks

AEROSPACE PARTS

DOUBLE PORTAL

AUTOMOTICE MOULD